There are several differences between Stainless Steel and PVC render beads, many of which are commonly misunderstood. The quality and longevity of a true stainless steel and pure PVC render bead are very closely matched. The choice of which bead to use often comes down the individual specifications of the job. So which one is best suited to your current render job?

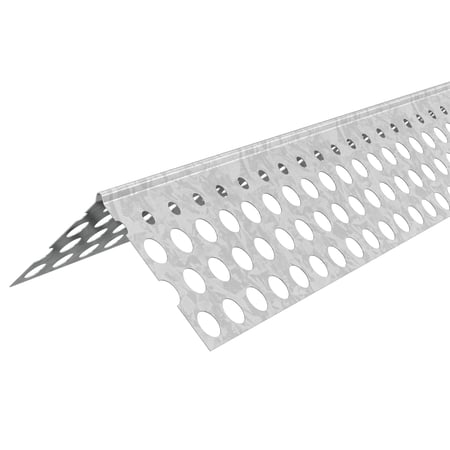

Stainless Steel Render Beads

Stainless steel render beads vary from 6mm up to 10mm in thickness and are used on sand/cement finishes. These beads are most commonly used in Western Australia and South Australia due to their suitability to the climate in these states.

Stainless steel render beads are the most expensive option. This is because most stainless steel beads are not manufactured in Australia; instead they are imported from overseas. In addition to this, the thickness of stainless steel beads means that a renderer will have to apply 2-3 layers of bag render to properly to cover the beads, creating an increased cost in materials.

The most common misperception about stainless steel render beads is that they are the highest quality render bead available on the market. In fact, due to the majority of the stainless steel beads on the market being manufactured overseas, the products are not made to suit the harsh conditions of the Australian climate.

Another consideration to make when purchasing stainless steel render beads is to ensure they are true stainless steel. Many products being imported are simply powder coated stainless steel. This means that within a short period of time of exposure to the weather elements, these render beads will most definitely rust. Once rusted, the colouring will bleed through the render and stain.

PVC Render Beads

PVC render beads range from 2.5mm – 10mm in thickness. PVC are most suitable to blockwork, brickwork, hebal block, also fibre cement sheeting and polystyrene finishes.

PVC render beads are the cheapest option on the market, but the reduction in cost is by no means a reduction in quality. Not only are PVC render beads cheaper to buy, but majority of the beads, depending on their thickness, will provide a reduction of costs in material also. This reduction in costs can be transferred into savings for your customers or even an increased profit margin for your business.

A large majority of the PVC render beads on the market are Australian made; therefore they are designed to withstand the harsh Australian conditions. They provide the same lifespan as a true stainless steel render bead and a quality PVC bead should provide the same strength.

A consideration to take into account when buying PVC render beads is to ensure they are UV stabilised. A non-UV stabilised PVC render bead will turn yellow and become distorted in a short period of time.

Pro Plaster Products provides a full range of PVC render beads. The Pro Trim PVC Range is Australian made for Australian conditions. The thicker, stronger, straighter beads are believed to be the best and most comprehensive range on the market.

They are UV stabilised and rust resistance, meaning they won’t become brittle and distort when exposed to sunlight or coastal conditions.

The Pro Trim range have thicker profiles, therefore they are more resilient against wear and tear. They are also made of pure PVC and are backed by a 10 year warranty to provide peace of mind for all users.

To view the full Pro Trim PVC Range follow the link below:

Pro Trim PVC Render Bead Range

To learn more about the Pro Trim range, follow the link below:

Pro Trim – Thicker, Stronger, Straighter PVC Render Beads

To learn more information about the range of render trims stocked by Pro Plaster call us today on 1800 652 267 or email sales@proplaster.com.au

Leave Comment